Process and characteristics

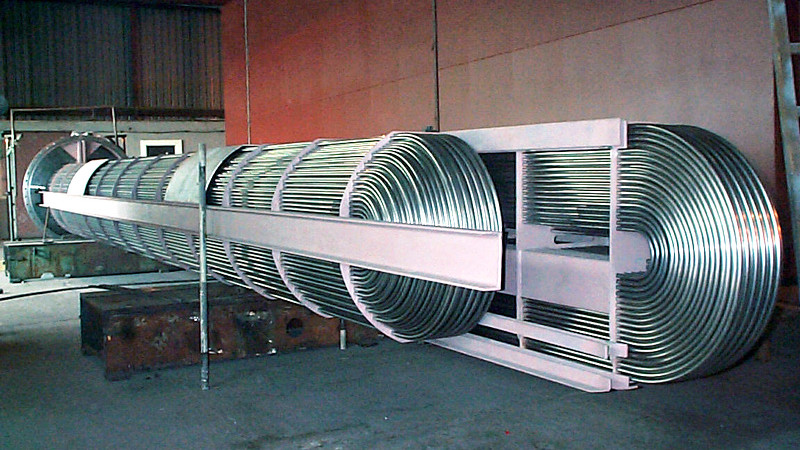

Since ZM Tubes is equipped with its own coil slitting line, it is fully flexible of modifying the final diameter at the very last moment. Strips are first formed along the width and then TIG (tungsten inert gas) or laser welded at the edges along the length. Welding is carried out without any filling material. Strong corrosion resistance, precise forming, excellent roughness of surface even along the welding area are the keys to success that make ZM Tubes a world-class supplier for heat exchangers, evaporators, condensers and feed water heaters. We deliver both straight and U-bent tubes with a length up to 30 meters.

Applications

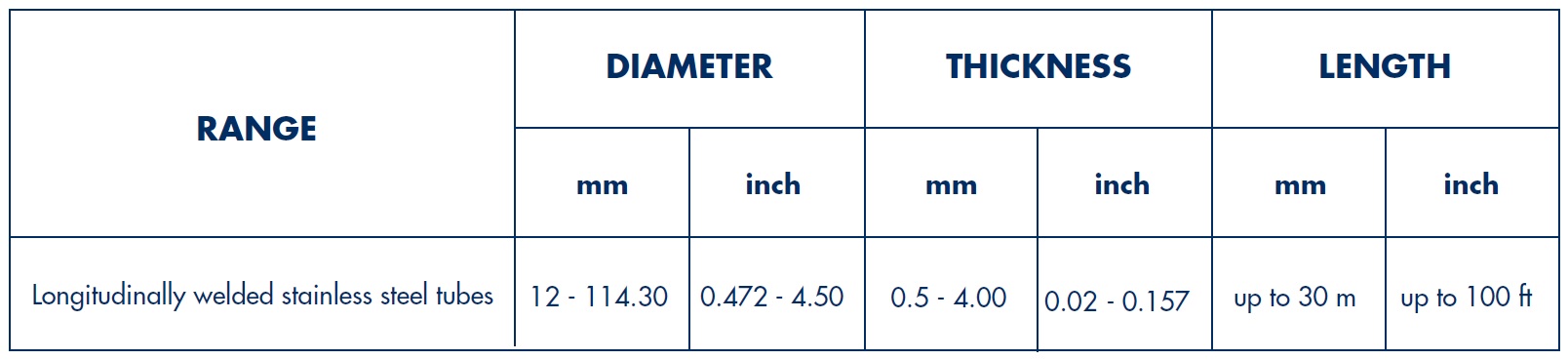

Production range