Our tubes

ZM Tubes mainly produces four kinds of stainless steel and nickel alloy tubes upon request:

Markets

These tubes are used in a wide range of applications as:

- heat exchangers, condensers, evaporators, feed water heaters for power plants;

- air coolers;

- equipment in the food industry;

- pharmaceutical industry;

- pneumatic sector;

- electromagnetic equipments;

- automotive industry;

- instrumentations;

- chemical and petrochemical sectors;

- valve and aerospace industries.

These tubes are used in a wide range of applications as heat exchangers, condensers, evaporators, feed water heaters for power plants and equipment in the food industry, as well as in the pharmaceutical, pneumatic, automotive, instrumentation, oil & gas, valves and aerospace industries.

Power plants

Pharmaceutical

Air coolers

Food industry

Chemical & petrochemical

Instrumentation

Pneumatic

Electromagnetic

Automotive

Heat exchangers

Semiconductors

High pressures

Inspection and testing

Inspection and tests are made in accordance with the execution standard.

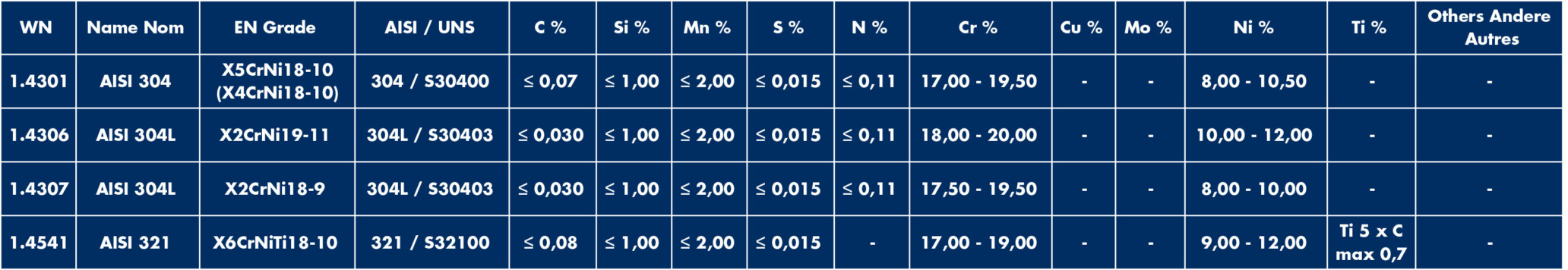

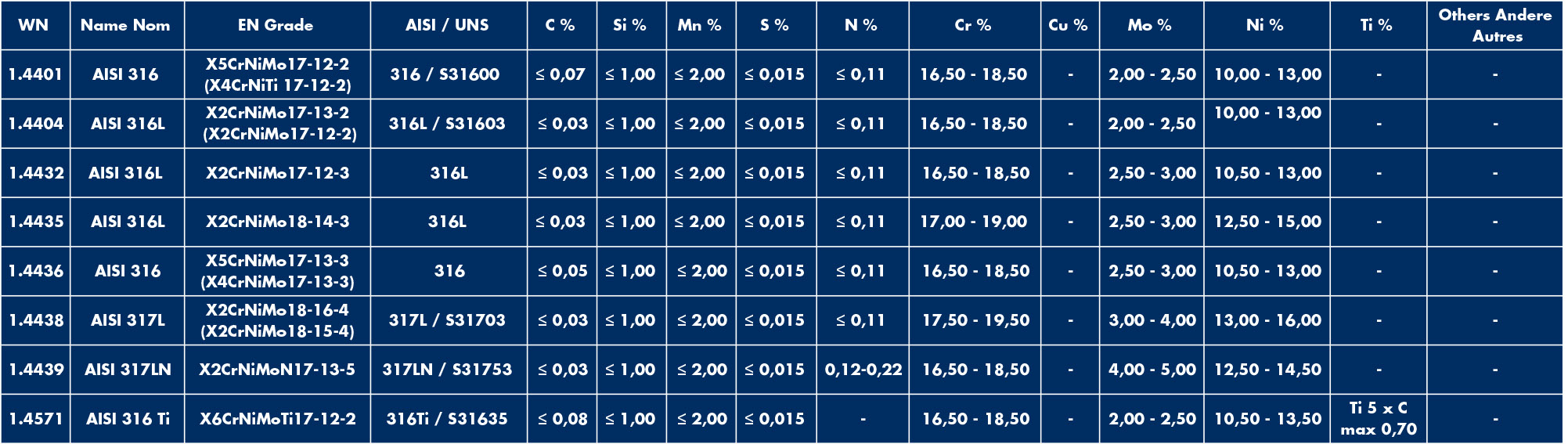

Stainless steel grades

- Austenitic

304/304L/316/316L/316SL/316TI/

321/317L/317LN

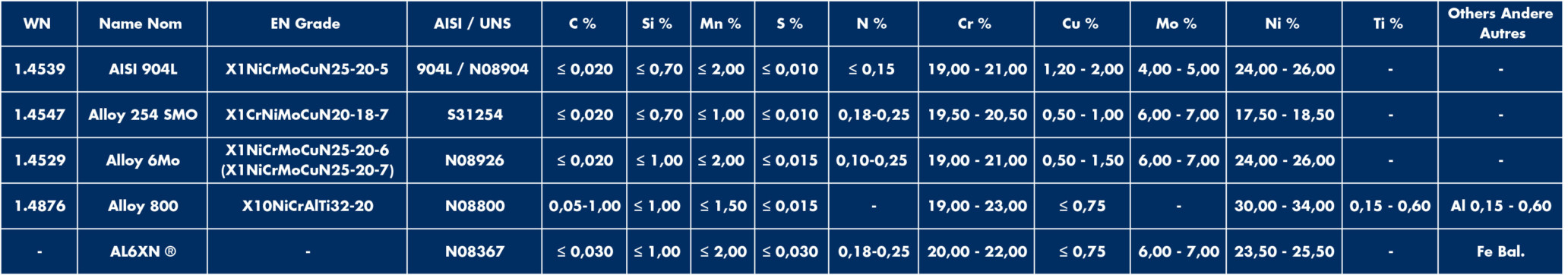

- Super austenitic

904L/254SMO/N08926/N08800/AL6XN

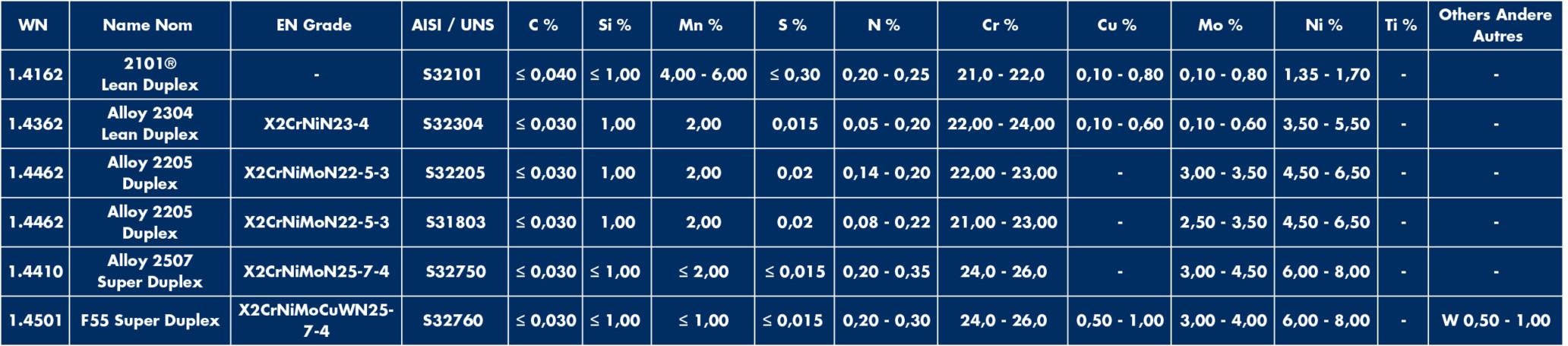

- Duplex

S32101/S32304/S32205/

S31803/S32750/S32760

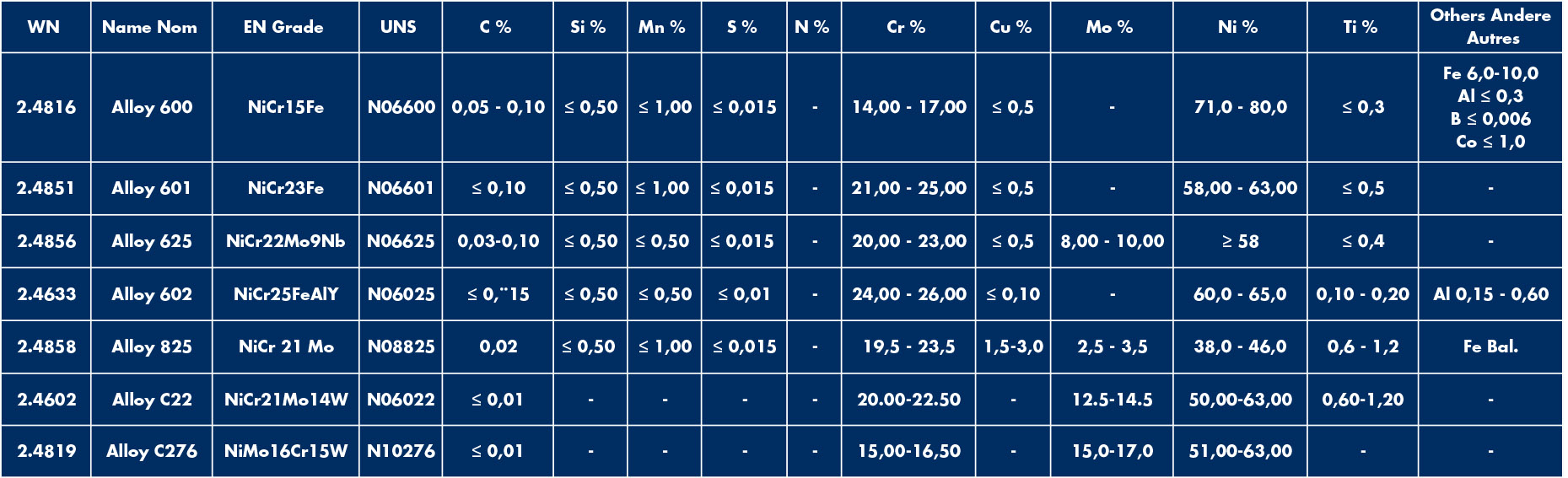

- Inconel

600/601/602/625/825

- Ferritic

S44100/S44400/S43035

- Heat resisting steels

310S/321H/304H

- Incoloy + Hastelloy

on request

Main standards

ASTM/ASME A

213, 249, 269, 270, 312, 688, 789, 790,1016

ASTM/ASME B

626, 674, 676, 704, 751, BPE

DIN

11866

EN

10217/10216-5, 10305, 10357, 10893

CUSTOMER SPECIFICATION

Execution

- Welded and seamless

- Welded and seamless redrawn for high precision application

- Seamless redrawn for high pressure application

- Brushed, polished

- Hard, 1/2 Hard, 1/4 Hard

- Bright annealed

- Annealed and pickled

Services

- Finned tubes (lowfin, embedded, applied and foot fins)

- Machining

- Polished

- Electropolishing inside

- U-tubes

Packaging

- Tubes are packed in bundles or in cages or wooden crates.

- It is possible to protect them individually with plastic film also in VCI.

- Special packaging is available on request.