Process and characteristics

Precision is not a matter of chance at Zwahlen & Mayr!

Thanks to 40 years of “Swiss made” experience, using highly skilled staff and continually investing in technological and solution improvements, we have managed to maintain our position at the highest level of redrawn precision technology.

Our mission is to produce state-of-the-art precision tubes, satisfying customer needs and developing worldwide long-term partnerships.

Our stainless-steel welded tubes are fully manufactured “in house” – from mother coil slitting up to standard welded tubes – which guarantees constant mechanical parameters, specific surface roughness and tight dimensional tolerances.

These tubes then go through a special redrawing process to achieve extreme precise characteristics as:

- narrow dimensional tolerances;

- ultra smooth surface with specific roughness outside and inside;

- specific mechanical values;

- very short tubes (min. 4 mm – 0.157 inch).

Outside surface tubes are supplied with different finish such as BA – bright annealed or polished.

Applications

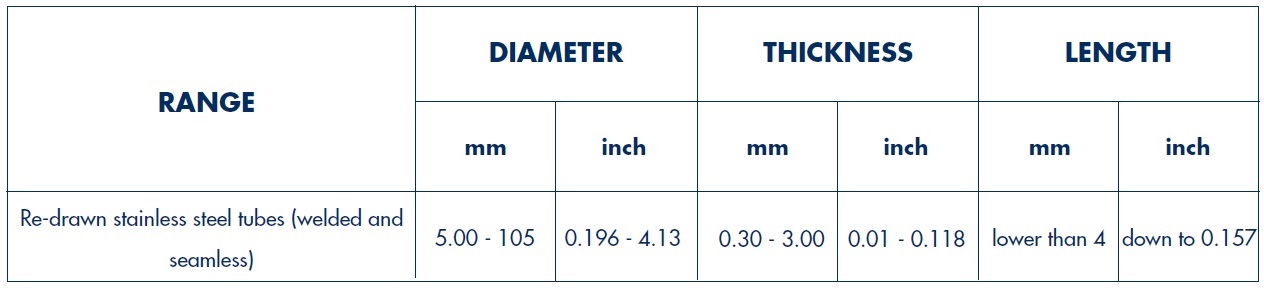

Production range