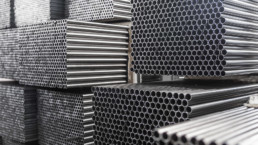

WELDED TUBES

Process and characteristics

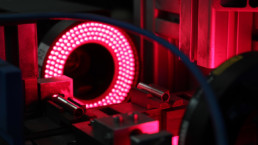

Since ZM TUBES is equipped with its own coil slitting line, it is fully flexible and able to modify the final diameter at the very last moment. Strips are first formed along the width and then TIG (tungsten inert gas) or laser welded at the edges along the length. Welding is carried out without any filling material.

Strong corrosion resistance, precise forming, and excellent roughness of surface even along the welding area are the keys to success that make ZM TUBES a world-class supplier of heat exchangers, evaporators, condensers and feedwater heaters. We deliver both straight and U-bent tubes with a length of up to 30 meters.

Applications

Conventional power stationsNuclear power stationsChemical and petrochemical plantsPetroleum refineriesPulp & PaperAir treatmentDairy

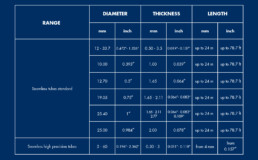

Production Range

Diameters 12 -114.3 mm 0.472 - 4.50 inchThickness 0.50 - 4.00 mm 0.02 - 0.157 inchLength up to 30 m up to 100 ftU-bent tubes

WELDED REDRAWN TUBES

Process and characteristics

Precision is not a matter of chance at Zwahlen & Mayr! Thanks to 40 years of “Swiss made” expertise, using highly skilled staff and continually investing in technological improvements, we have managed to maintain our position at the highest level of redrawn precision technology. Our stainless steel welded tubes are fully manufactured “in house” from mother coil slitting up to standard welded tubes which guarantees constant mechanical parameters, specific surface roughness and tight dimensional tolerances.

These tubes then go through a special redrawing process in order to achieve extremely precise characteristics, such as: Narrow dimensional tolerances, Ultra smooth surface with specific roughness outside and inside, Specific mechanical values, Very short tubes (min. 4 mm - 0.157 inch). Outer surface tubes are supplied with different finish such as BA bright annealed or polished.

Applications

Automotive and aerospacePharma, food and chemical industryMechatronicsPneumaticOil & GasInstrumentationSeveral critical industrial purposes

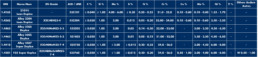

Production Range

Diameters 5.00 - 105.00 mm 0.196 - 4.13 inchThickness 0.30 - 3.00 mm 0.01 - 0.118 inchLength from 4 mm from 0.157 inch

SEAMLESS STAINLESS STEEL TUBES

Process and characteristics

Strong corrosion resistance, perfect tightness, manufacture thanks to the most advanced production technologies are the keys to success that make ZM Tubes a world-class supplier for heat exchangers, evaporators, condensers and heaters.We deliver both straight and U-bent tubes with a length of up to 24 meters.

Our stainless steel seamless high precision tubes are customized according to our client’s specification to meet exactly their expectation. We can guarantee a constant quality, specific surface roughness and very tight dimensional tolerances. These tubes go through a special redrawing process in order to achieve extremely precise characteristics as:Narrow dimensional tolerancesUltra smooth surface with specific roughness outside and insideSpecific mechanical valuesVery short tubes (min. 4 mm - 0.157 inch)

Applications

Chemical and petrochemical plantsPower stationsPetroleum refineriesFood and dairyAutomotive and aerospacePharma and chemical industryMechatronicsPneumaticOil & GasInstrumentationSeveral critical industrial purposes

Main Standards

EN 10216-5ASTM A 213ASTM A269ASTM A789